SNIPE

BOTTLE INDUCTION SEAL INTEGRITY INSPECTION

SNIPE

HEAT SEAL INTEGRITY INSPECTION

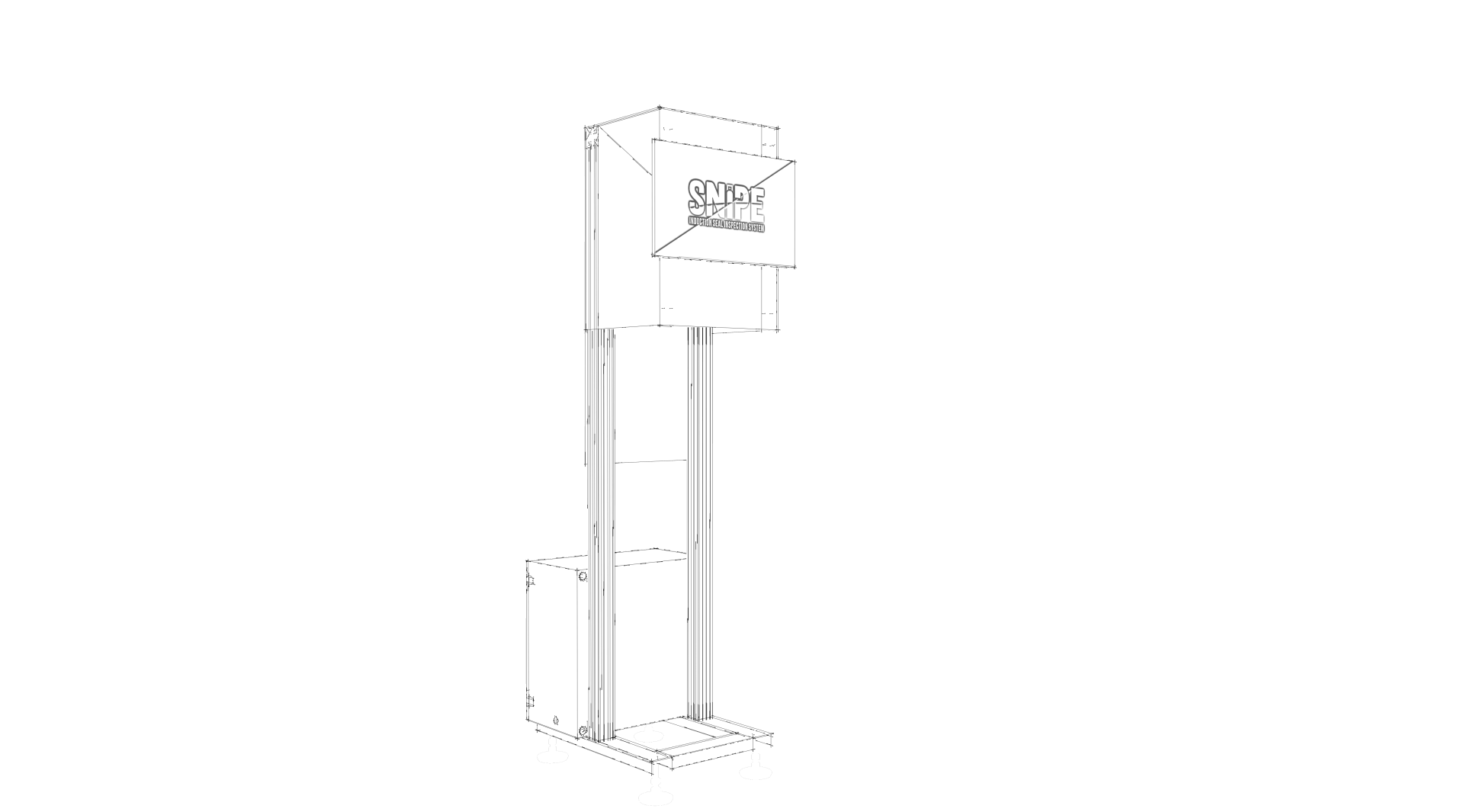

SNIPE D

HEAT SEAL INTEGRITY INSPECTION

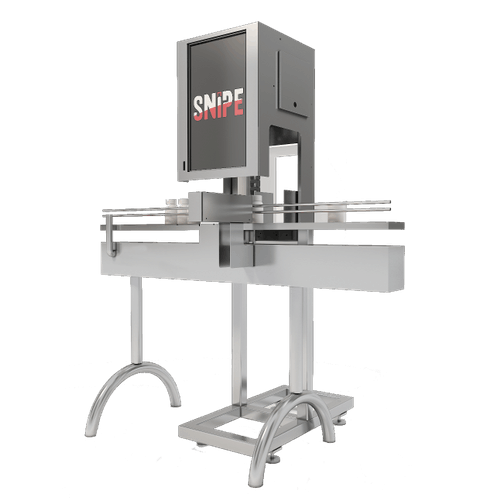

Snipe is an online heat seal inspection system that retrofits onto existing packaging lines.

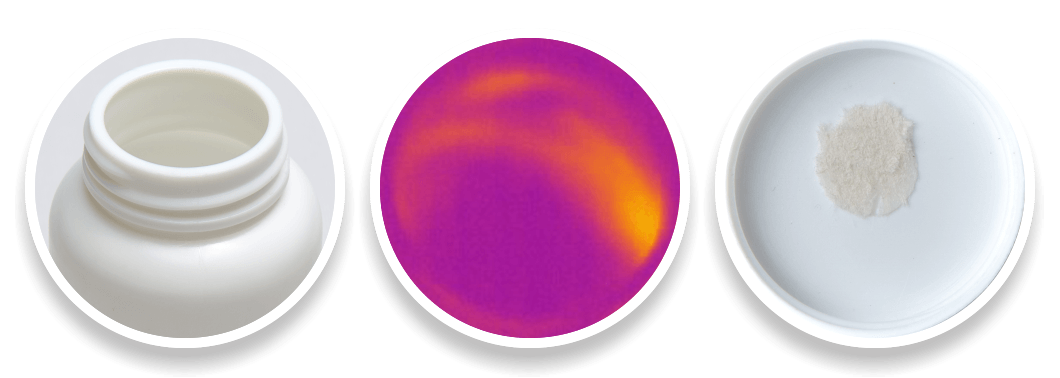

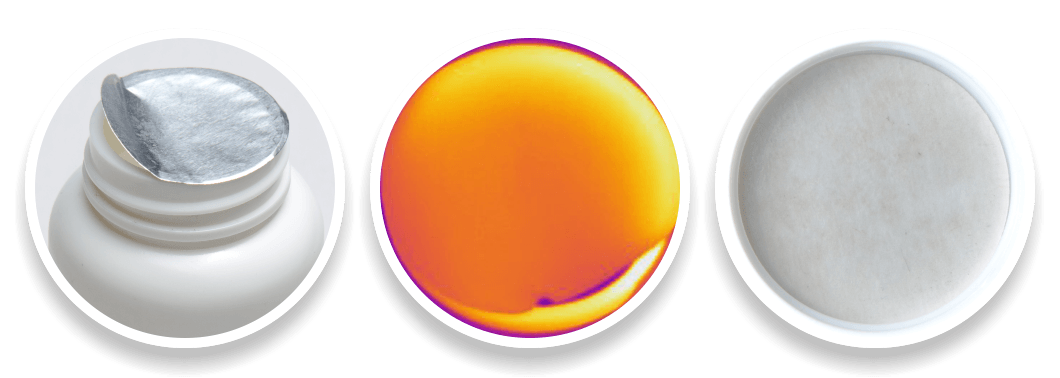

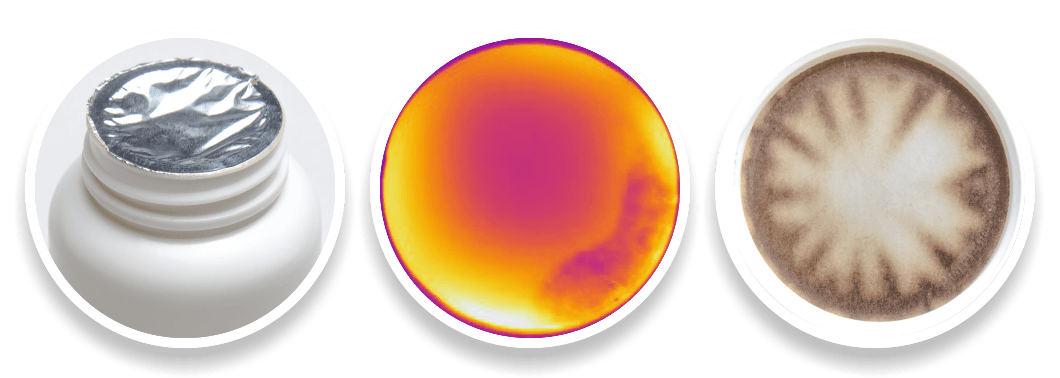

Poor induction seal quality remains a serious concern in the FMCG instustry. Sub-standard seals can comprimise product integrity, lead to spillages later in the production process and even cause major public health risks.

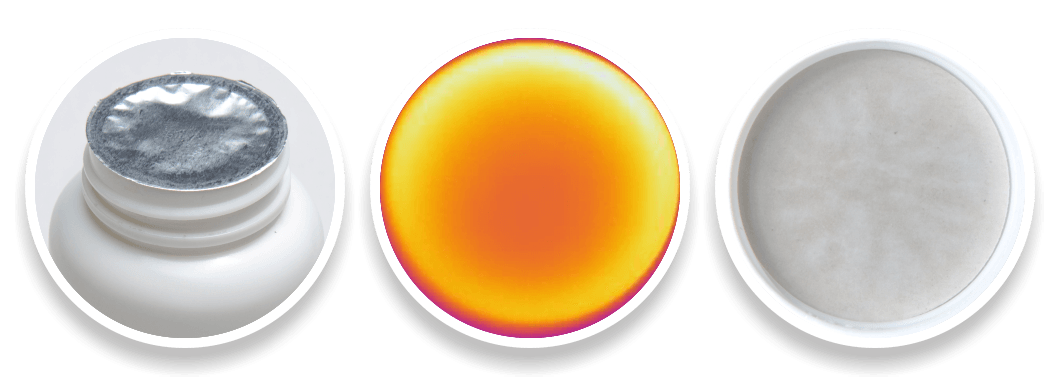

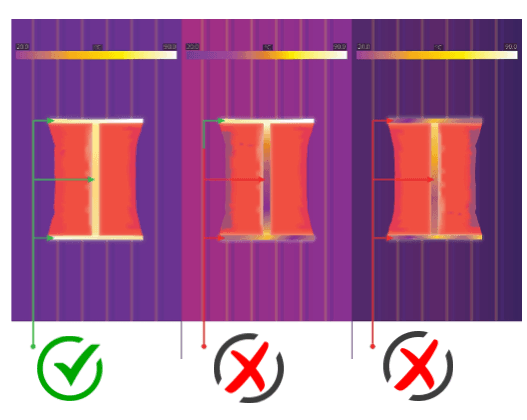

Using the latest in high resolution thermal technology, Snipe accurately detects any areas of potential leakage or damage to a seal, verifying the integrity of the packaging and rejecting any defective products.

Configurable for packaging of most standard dimensions, the system has also been designed with a high level of versatility.

This technology can also be installed in-line, meaning minimal impact on existing production processes.

IN ACTION

- Compact and accessible

- High precision and speed

- Automated system calibration

- Online rejection system

- Real-time/Archived statistics and analysis

- Remote operation

- Extensive service package

- High resolution thermal inspection

- Up to 300 products per minute standard configuration

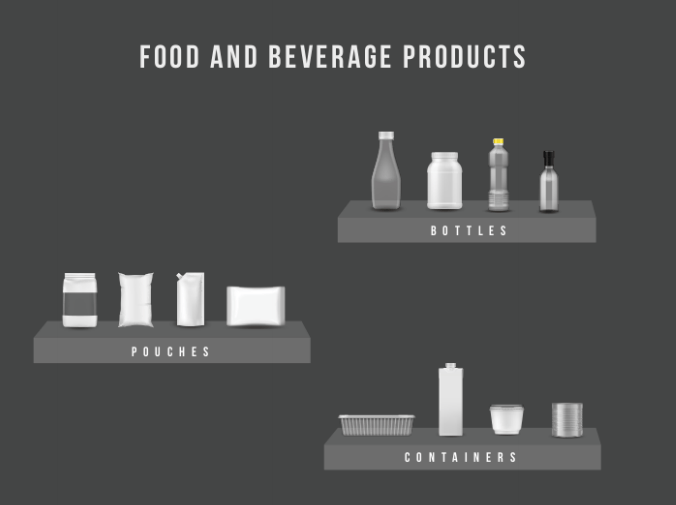

- Compatible with range of products (Pillow bags, pots, pouches, etc.)

- Compatible with range of different packaging machines

- Range of sizes: 20mm - 350mm and beyond

- Intuitive touchscreen HMI display

For more detailed specifications download the product brochure